Quality Control

- 5-year warranty for driving part, and 1-year warranty for electronical parts and wearing parts.

- Easy inspection and maintenance for parts on forming table.

- All parts under forming table should be lubricated every four to six month with specified oil.

Mechanical Properties

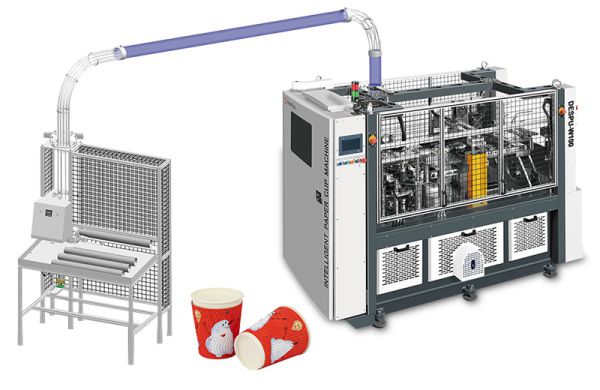

DESPU-C120 paper cup forming machine possesses a working table, which well separated driving part and molds, allowing easy cleaning and maintenance. Automatic lubricant spraying system, vertical shaft driving structure, cylindrical indexing CAM mechanism and gear driving system all help to ensure the stability and quality of this machine. Besides, DESPU-C120 also adopts PLC, photoelectric tracking and servo feed system to control the electronical parts.

-

-

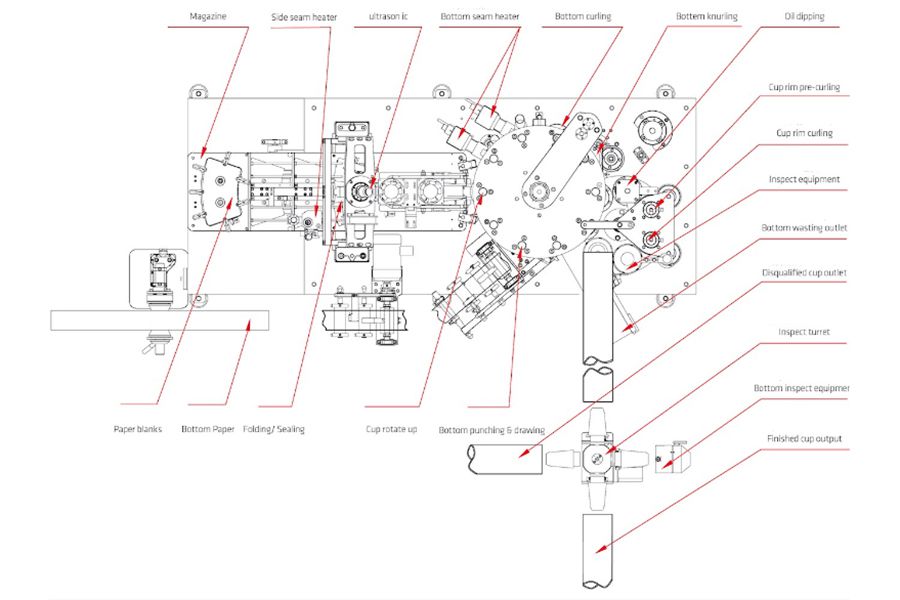

Driving mechanism

Longitudinal axis driving structure and cylindrical indexing CAM mechanism optimize inside structure and help to ensure high driving precision and excellent synchronization. In this way, the working of different parts can be well coordinated, thus to avoid disturbance of different working parts and to eliminate the chain joggling and driving instability.

-

-

Chassis Structure

Machine is designed with chassis structure, with welded ribs on its sides. Spaying lubrication is adopted to reduce wear and to improve cooling effect efficiently, thus to ensure the fast operation of this machine. 5-year warranty for the whole machine is provided (except wearing parts).

-

-

Double Curling

First curing adopts rotational moulding and expansion rings for high paper forming strength; Second curling adopts heating ring for better forming, perfect curling effect and even cup size.

-

-

Image Inspection System

1. From the top, stains and insects inside the cups or bowls, as well as the wearouts and wrinkles on the cup/bowl top can be easily detected.

2. From the bottom, stains, insects, warping in knurling areas and cup or bowl bottom, as well as yellowing and other problems can be easily detected.

Specification

| Model | DESPU-C120 |

| Output | 100-120 pcs/min |

| Dimension(oz) | 16---22oz |

| Application | coffee, tea, hot drinks |

| Cup Shape | |

| Paper Type | Single-sided PE/ Double-sided PE/PLA |

| Paper Thickness | 0.345-0.455mm |

| Cup Size | (D1)ф70-95mm (H)130-180mm

(D2)ф50-75mm (h)5-12mm |

| Power | 3-phase 380V,26KW |

| Compressed Air | 0.6-0.8MPa,0.5m³/min |

| Inspection | ○ |

| Bottom Heating | Assembling● |

| Extended Paper Conveying | ○ |

| Control Panel | 7 inches |

| Weight | 3500kg |

| Packaging Box Size | Normal type:3100 x 1600 x 2100mm

(cup counting shelf:1230 x 610 x 1900mm)

Inspection type:3100 x 1600 x 2350mm

(cup counting shelf: 1230 x 610 x 1900mm) |

Note: Optional Configuration ○ Standard Configuration ●

Process

Paper suction

Paper suction Side heating

Side heating Folding/Sealing

Folding/Sealing Bottom feeding

Bottom feeding Bottom heating 1

Bottom heating 1 Bottom heating 2

Bottom heating 2 Bottom curling

Bottom curling Bottom knurling

Bottom knurling Oil dipping

Oil dipping Top curling 1

Top curling 1 Top curling 2

Top curling 2 Cup discharging

Cup discharging

With more than 20 years experience in paper cup forming, DESPU develops, manufactures and markets paper cup forming machinery. Dedicated in providing complete solutions, DESPU helps you offer your customers best paper containers.With extensive research and development, it has successfully developed three generations of paper cup forming machines and now we are working for the forth. Get our paper cup forming solutions of highest quality and manufactured using the latest techniques to boost your global competition and enhance your product reputation in the market. As a highly innovative company, DESPU is able to produce varied paper cup and container forming machines, paper cup outer sleeve machines and auxiliary equipment. DESPU is devoted to meet your needs with excellent manufacturing capacities.