Routine Maintenance

For trouble-free operation, the operator must understand the operation of the machine and the process of forming the paper cups (bowls). The machine is a combination of different parts, each of which has its own unique function in the production process. Therefore, it is very important to fully understand the characteristics of the machine by reading the operating instructions.

Only regular maintenance of the paper cup machine can improve the working conditions, keep the paper machine in good working condition and extend its service life. You should do as follows:

- Deliver inspections every day and lubricate all joints and moving parts above the machine.

- Check that the cylindrical pins of the connecting parts are not loose and that the clasp is in its normal position. If there is any deformation or displacement, remove it and replace it immediately with new one.

- Check all fasteners: e.g. nuts, bolts. If any of them is loose, tighten it promptly; otherwise they may lead to serious vibration or other serious problems.

- All operators or maintenance mechanics must be aware of the noise or unusual signs during production. If this happens, the machine should be stopped immediately and thoroughly inspected.

- Only qualified personnel should carry out refurbishment work to ensure the safety of personnel and machines.

- The temperature control of the heater should be carefully set according to the product size and material characteristics. If the temperature is too high, it may lead to rim breakage or bottom leakage.

- The bottom knurling device is one of the important parts in the cup machine. If the knurling pressure is over-regulated, it will be worn and the life time will be shortened. For machines with ultrasonic welding of the side seams, working frequency need to be noted. Attention also needs to be paid to the contact surface, which must be evenly contacted at the proper pressure.

- The lubrication system must be regularly refueled, regularly changed and regularly cleaned. For manually lubricated parts of the machine, a proper lubrication schedule should be established; the first change for new machines should be 30 days; after that, you may extent it to every 6 to 12 months, depending on the condition of the oil.

- The oil pump inlet filter of the lubrication system should be cleaned regularly to avoid clogging of the oil pipe. New machines should be cleaned once a week for the first two months and then every two weeks to ensure the oil flows smoothly.

- The optical sensor needs to be cleaned regularly, usually once every 3 to 5 working days, to ensure the sensitivity of the Inspection.

- Blower intake filters should be cleaned once a week to ensure adequate air flow.

- For manually lubricated parts of the machine, make sure they are regularly oiled and cleaned according to the lubrication schedule.

For more information, please contact us and our sales will contact you as soon as possible (usually within 24 hours).

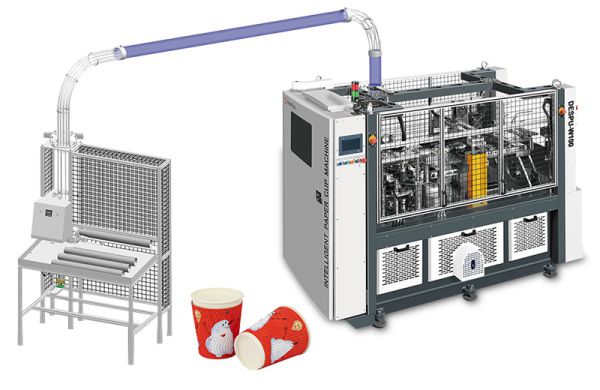

With more than 20 years experience in paper cup forming, DESPU develops, manufactures and markets paper cup forming machinery. Dedicated in providing complete solutions, DESPU helps you offer your customers best paper containers.With extensive research and development, it has successfully developed three generations of paper cup forming machines and now we are working for the forth. Get our paper cup forming solutions of highest quality and manufactured using the latest techniques to boost your global competition and enhance your product reputation in the market. As a highly innovative company, DESPU is able to produce varied paper cup and container forming machines, paper cup outer sleeve machines and auxiliary equipment. DESPU is devoted to meet your needs with excellent manufacturing capacities.