Quality Control

- 5-year warranty for driving part, and 1-year warranty for electronical parts and wearing parts.

- Easy inspection and maintenance for parts on forming table.

- All parts under forming table should be lubricated every four to six month with specified oil.

Mechanical Properties

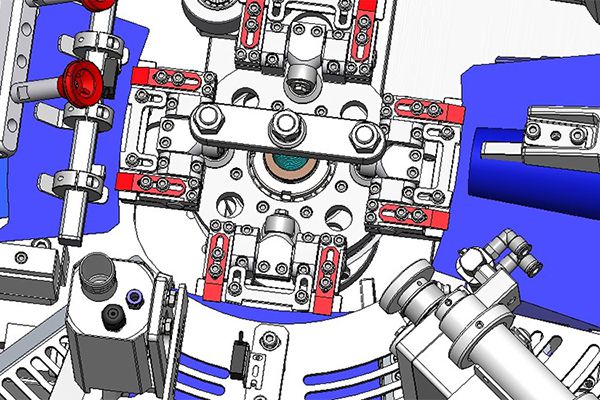

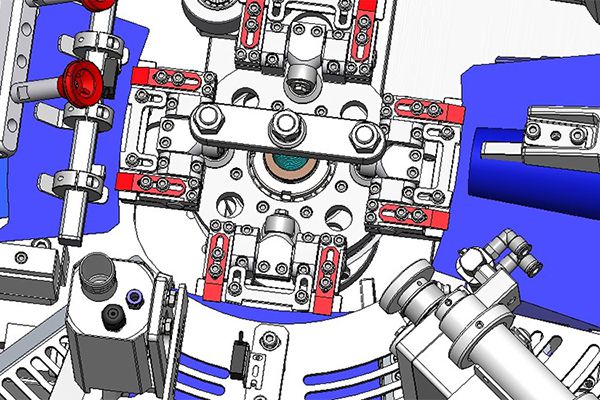

DESPU-C160 paper cup forming machine possesses a working table, which well separated driving part and molds, allowing easy cleaning and maintenance. Automatic lubricant spraying system, vertical shaft driving structure, cylindrical indexing CAM mechanism and gear driving system all help to ensure the stability and quality of this machine. Besides, DESPU-C160 also adopts PLC, photoelectric tracking and servo feed system to control the electronical parts.

-

-

Driving mechanism

Longitudinal axis driving structure and cylindrical indexing CAM mechanism optimize inside structure and help to ensure high driving precision and excellent synchronization. In this way, the working of different parts can be well coordinated, thus to avoid disturbance of different working parts and to eliminate the chain joggling and driving instability.

-

-

Chassis Structure

Machine is designed with chassis structure, with welded ribs on its sides. Spaying lubrication is adopted to reduce wear and to improve cooling effect efficiently, thus to ensure the fast operation of this machine. 5-year warranty for the whole machine is provided (except wearing parts).

-

-

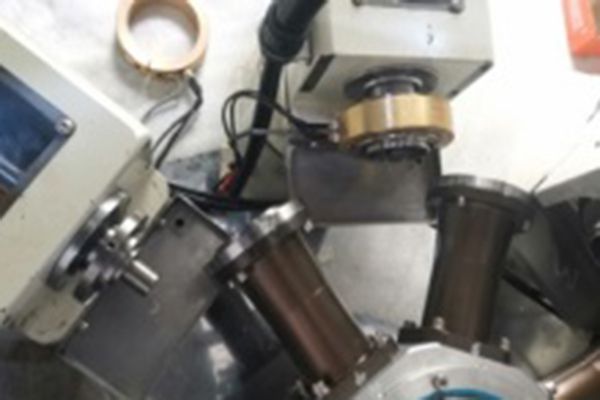

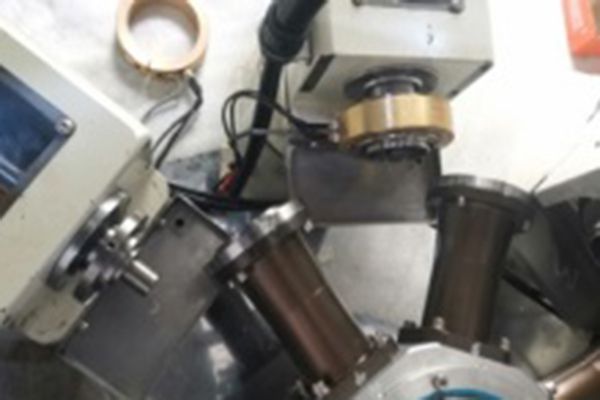

Double Curling

First curing adopts rotational moulding and expansion rings for high paper forming strength; Second curling adopts heating ring for better forming, perfect curling effect and even cup size.

-

-

Image Inspection System

1. From the top, stains and insects inside the cups or bowls, as well as the wearouts and wrinkles on the cup/bowl top can be easily detected.

2. From the bottom, stains, insects, warping in knurling areas and cup or bowl bottom, as well as yellowing and other problems can be easily detected.

-

-

Stability

Longitudinal axis driving structure and cylindrical indexing CAM mechanism optimize inside structure and help to ensure high driving precision and excellent synchronization. In this way, the working of different parts can be well coordinated, thus to avoid disturbance of different working parts and to eliminate the chain joggling and driving instability.

-

-

Box structure design and oil spray lubrication system reduce wear and to improve cooling effect efficiently, thus to ensure the fast operation of this machine. Due to chassis structure and insulated bottom& top, oil only needs to be changed 2 times each year(once every 6 months). It allows easy maintenance and low oil cost. Because of the unclosed structure of other machines, paper dust and waste may fall down to bottom. Therefore, same lubrication effect can only be achieved for other companies when oil is changed once every month.

-

-

France Schneider and Rexroth electrical parts. PLC control system & touch screen with sensors. Paper feeding with servo to reduce waste. Any breakdown occurs, it will auto-stop and show on screen for easy checking. With electronic cam, paper suction rod’s position can be adjusted on screen. Compared with other factories’ manual temperature control system with spin button, PID temperature control system, which can be set on screen, leads to zero errors.

-

-

The paper suction process adopts three-degree paper suction + high-speed rotating mechanism + four-minute servo paper feeding, allowing a theoretical design speed of 200-238 pieces/min. In this way, paper suction and paper removal system are more stable than 138S vertical machine. Besides, failure rate caused by poor paper suction is greatly reduced.

-

-

Three side sealing structures: in accordance with paper thickness, three side sealing techniques are optional. After fixing cup body on case mold, cup-top curling and heat forming will be adopted for smooth and thin curling effect, as well as better forming effect.

-

-

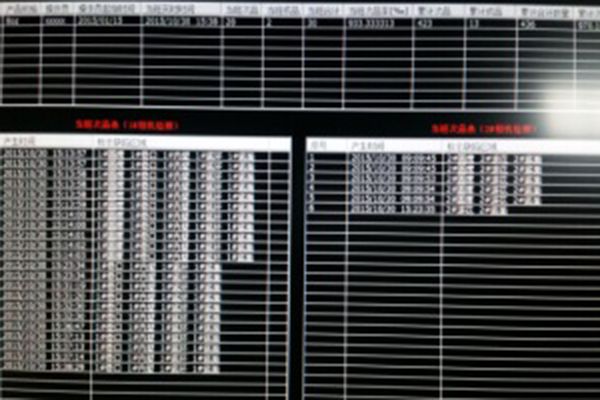

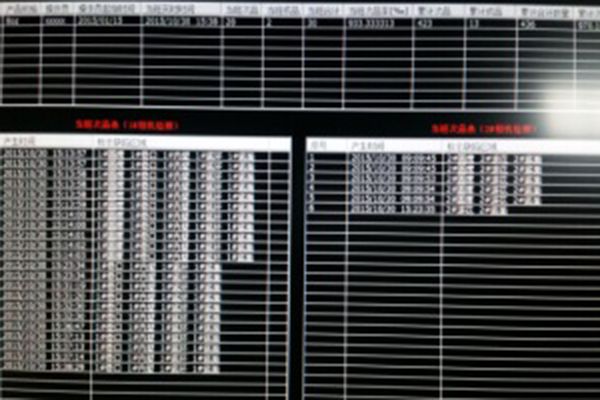

It will conclude all working data report on screen in certain time(daily/monthly/ yearly).

-

-

Double Curling

First curing adopts rotational moulding and expansion rings for high paper forming strength; Second curling adopts heating ring for better forming, perfect curling effect and even cup size.

-

-

High quality materials—Stretching bottom paper die

cutter, Cr12Mov mold steel. Aviation aluminum for cup molds. Therefore, all materials are of high hardness and anti-friction.

Intelligent Control System

- Frames of multiple models. Easy selection and operation with clear directions.

- Easy setting for parameters. Data back-up, recovery and factory setting can be achieved. Manual setting is also available.

- Program origin and direction can be automatically set. No failure will be missed from self-Inspection system. When installing encoder’s hardware, you only need to set the software data rather than considering hardware’s installation position.

- Automatically stop at certain place and lower itself rapidly within one round. After setting, machine’s inertial running distance will be automatically measured, at least one step further than the position reached after slowdown.

- Signal in key areas can be automatically counted and recognized. Once there is any failure in forming process, the system will automatically track the signals according to the sensors, and stop the mold between two heaters.

- Cup will be automatically fetched out when failure occurs. Unexpected stop may lead to the burned-out heater and the unfirm adhesive, so heater and frame will be automatically removed.

- Intelligent temperature control for heating system. PLC and PID temperature control system are applied. Targeted temperature will be automatically set when users input the manufacturer, weight, single or double PE coated of papers. Besides, when targeted temperature changed, the production efficiency will have a change as well. Users can also customize the targeted temperature curve.

- Appearance inspection system. Cup shape and flaws inside and outside the cup can be automatically recognized and removed. With unique arithmetic method, this machine can locate the light gray stains easily and correctly. Parameters can be set and changed easily. Report in internal monitoring can also be output.

- Hardware monitoring system. PLC input, relays, contactors, PLC and touch screen, PLC and computer. PLC can timely monitor the expanded lines. When failure occurs, alarm will be sounded and the failure cause, detailed information about faulted software or hardware will be reminded. In this way, faults can be easily removed.

- Long-distance upgrading is available. When high speed Ethernet is used to connect PLC and touch screen, IP address of PLC and touch screen can be revised. Besides, long-distance upgrading can be achieved with NAT or other internet providers.

Specification

| Model | DESPU-C160 |

| Output | 120-160 pcs/min |

| Dimension(oz) | 5-16oz |

| Application | coffee, tea, hot drinks |

| Cup Shape | |

| Paper Type | Single-sided PE/ Double-sided PE/PLA |

| Paper Thickness | 0.295-0.445mm |

| Cup Size | (D1)ф60-95mm (H)50-135mm (D2)ф40-75mm (h)5-12mm |

| Power | 3-phase 380V,26KW |

| Compressed Air | 0.6-0.8MPa,0.5m³/min |

| Inspection | ○ |

| Bottom Heating | Assembling● |

| Extended Paper Conveying | ○ |

| Control Panel | 10.2 inches |

| Weight | 3400 kg |

| Packaging Box Size | Normal type: 100 x 1600 x 2100mm (cup counting shelf: 1230 x 610 x 1900mm)

Inspection type: 3100 x 1600 x 2250mm (cup counting shelf: 1230 x 610 x 1900mm) |

Note: Optional Configuration ○ Standard Configuration ●

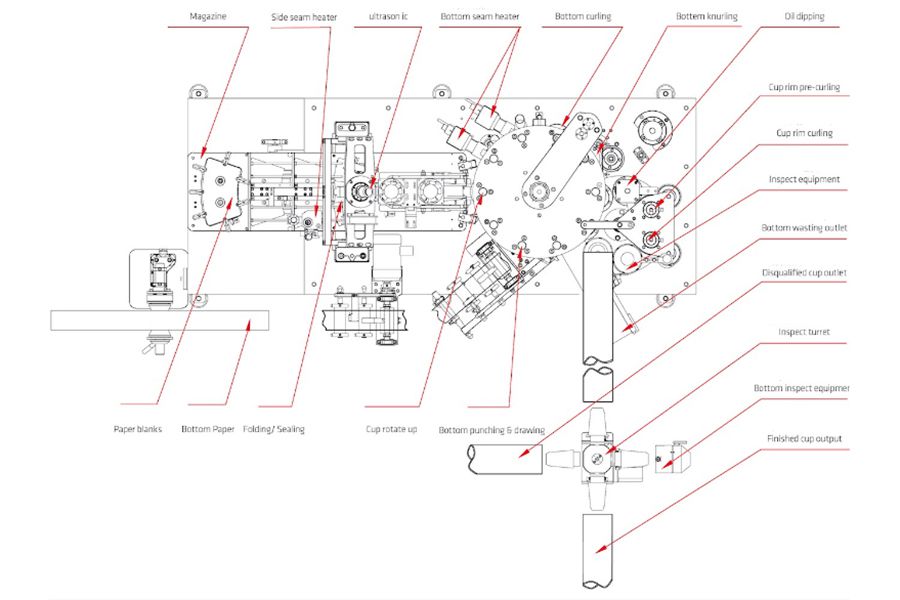

Process

Paper suction

Paper suction Side heating

Side heating Folding/Sealing

Folding/Sealing Bottom feeding

Bottom feeding Bottom heating 1

Bottom heating 1 Bottom heating 2

Bottom heating 2 Bottom curling

Bottom curling Bottom knurling

Bottom knurling Oil dipping

Oil dipping Top curling 1

Top curling 1 Top curling 2

Top curling 2 Cup discharging

Cup discharging

Recommended

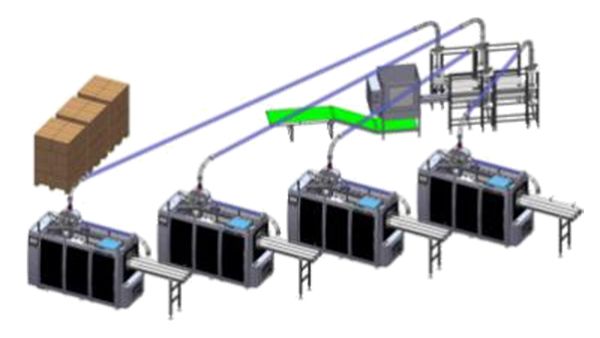

Combination Scheme A

4 sets C160 with detector&paper feeder table

+1 set automatic 1 set packing machine

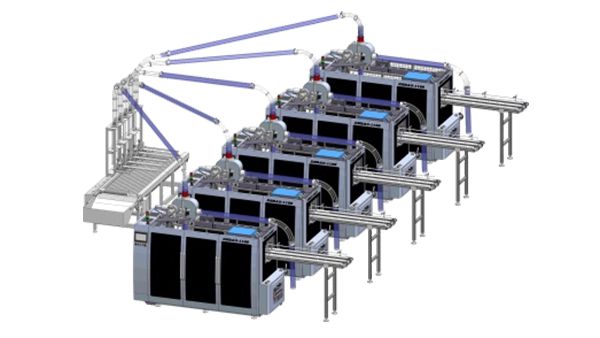

Combination Scheme B

5 sets C160 with detector&paper feeder table

+1 set automatic 1 set cup collection table

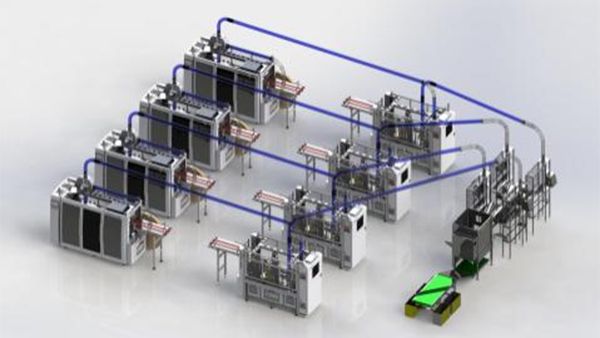

Combination Scheme C

4 sets C160 with detector&paper feeder table+4 sets W100 with paper feeder table

+1 set automatic 1 set packing machine

With more than 20 years experience in paper cup forming, DESPU develops, manufactures and markets paper cup forming machinery. Dedicated in providing complete solutions, DESPU helps you offer your customers best paper containers.With extensive research and development, it has successfully developed three generations of paper cup forming machines and now we are working for the forth. Get our paper cup forming solutions of highest quality and manufactured using the latest techniques to boost your global competition and enhance your product reputation in the market. As a highly innovative company, DESPU is able to produce varied paper cup and container forming machines, paper cup outer sleeve machines and auxiliary equipment. DESPU is devoted to meet your needs with excellent manufacturing capacities.